News & Views

News & Views

Things are humming along nicely when all of a sudden, your electrical supply: kaput. It can happen any day, at any hour, and beyond the inconvenience, an unplanned electrical outage is costly and worse – highly dangerous.

How’s this for a motivating statistic: 22% of industrial fires are caused by faulty electrical equipment. With this kind of liability, prevention is better than cure. In response, Thermal Imaging is emerging as a top tech for building maintenance. And in turn, insurance companies cost-cut for businesses implementing proactive strategies to reduce risk.

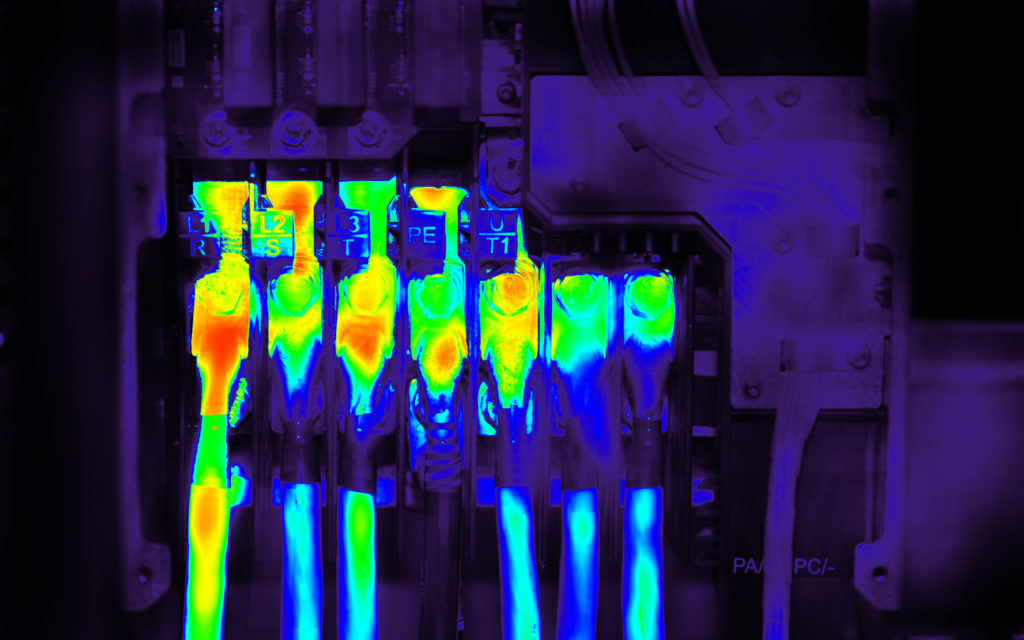

Otherwise known as thermography, Thermal Imaging uses a sophisticated electrical thermal imaging camera to calculate the infrared radiation (heat) an object gives off. This data is then used to compose images of these objects, even in low-light environments. Emitted energy, known as ‘heat signature,’ is then transformed into a distinctive colour gradient that portrays temperature variation accurate to one-tenth of a degree. In these greyscale images, white equals heat, black equals cold, and the greys show temp gradients between the extremes. Some cutting-edge models include colour.

A virtually undetectable tool, you want Thermal Imaging on your side to expose problems, keep your workplace assets safe and save on spendy repairs. Rest assured, knowing your building inhabitants are safe and sound. For an office building, a Thermal Imaging scan is recommended every 2-3 years. Manufacturing sites experience a high-power drain on electrical systems, requiring a more frequent scan each year.

An electrical infrared inspection can stave off electrical failure and find overheated parts in electrical devices and switchboards. Detect hot spots caused by loose electrical connections, unstable loads, overloading on electrical circuits and degrading insulation or wire damage waged by pests. Thermography scanning of the switchboard is a highly effective means of mitigation.

Thermal Imaging has more than one purpose. Across all of its applications, the practice has racked up some impressive benefits. Here are ten:

Prevention is better than cure – it’s worth saying twice. Thermal imaging of electrical panels is a top tool for recognising stressed elements of your electrical system before they cause issues. In a nutshell – solve the problem as a matter of planned maintenance before it causes you strife. Instead of relying on protection systems like sprinklers to keep risk at bay, Thermal Imaging lets you locate potential problems invisible to the naked eye. Avoid downtime, and don’t risk putting property and lives in danger.

Please chat with our team of electrical specialists to find out more or book your thermal inspection. Put this intelligent process in motion and take the heat off risks to your building.

Related Resources: